CTS - Car Tire Scan

360° Tire Profile Measurement System on a Vehicle

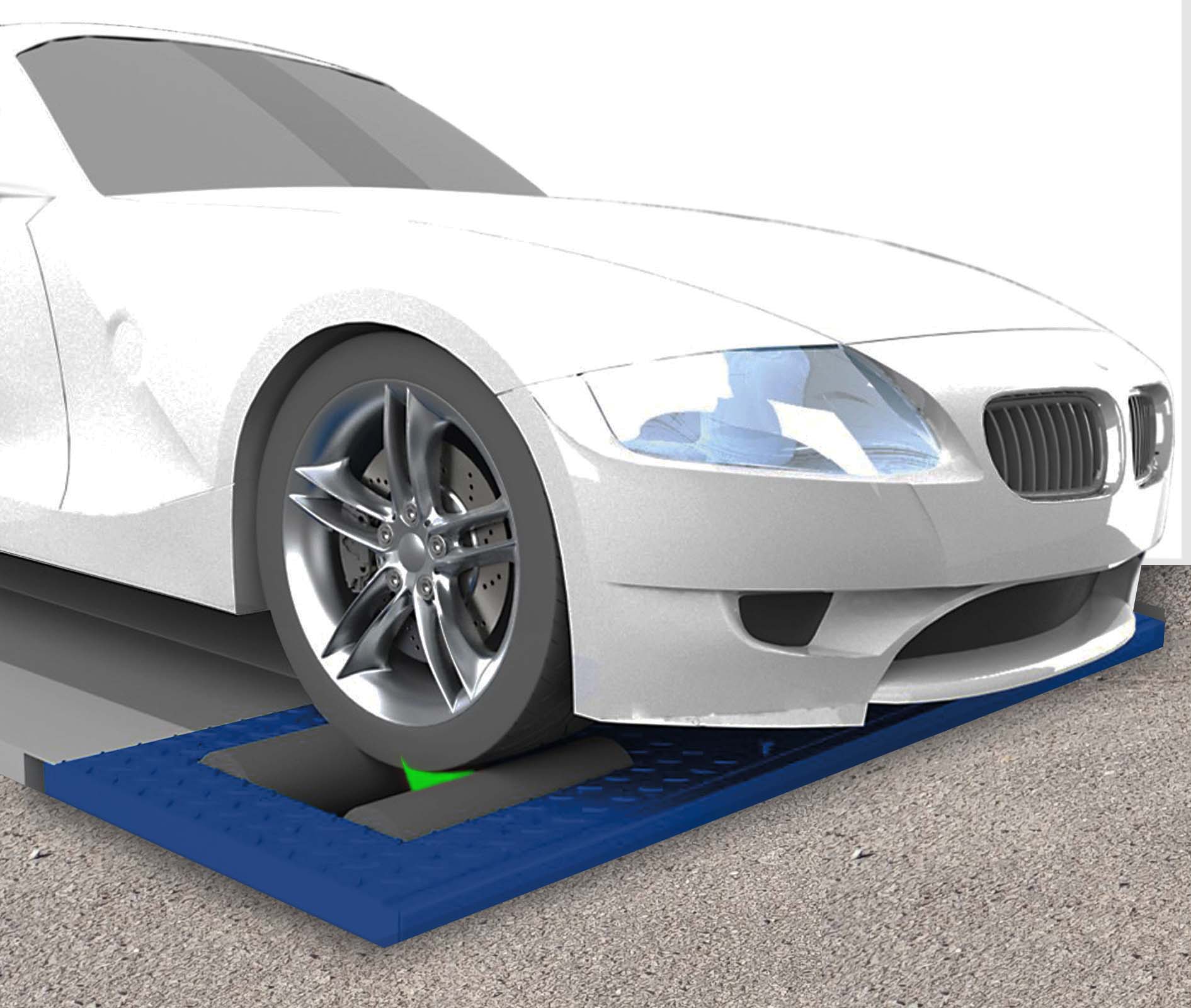

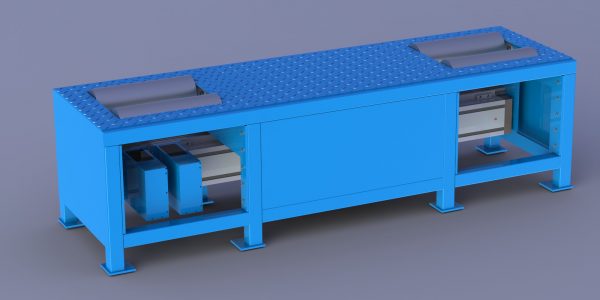

The CTS system offers a fast measuring technique for 2 mounted tires on the vehicle. The complete system is designed as a roller test bench with laser-light-intersection-sensors which can be driven over with the vehicle for measurement. With the identical functions of the TriScanTire measurement system for profile evaluation and wear analysis, the CTS is an effective and ergonomic alternative. The results of the 360° 3D tread surface analysis are also compatible with TST - TriScan Tire user interface.

The concept of the CTS system allows the measurement of both tires of one axis one after the other in the same measuring process. After measuring the first side, the sensor system will be automatically driven to the other side of the vehicle by linear guides. focus is on the measuring period of under 10 seconds per wheel, which makes the system not only interesting for garages and testing facilities. Tire manufacturers also value the time saving and the measuring after every test drive. Above all the CTS system can be integrated as a solo test bench for final checking of tires in production lines.

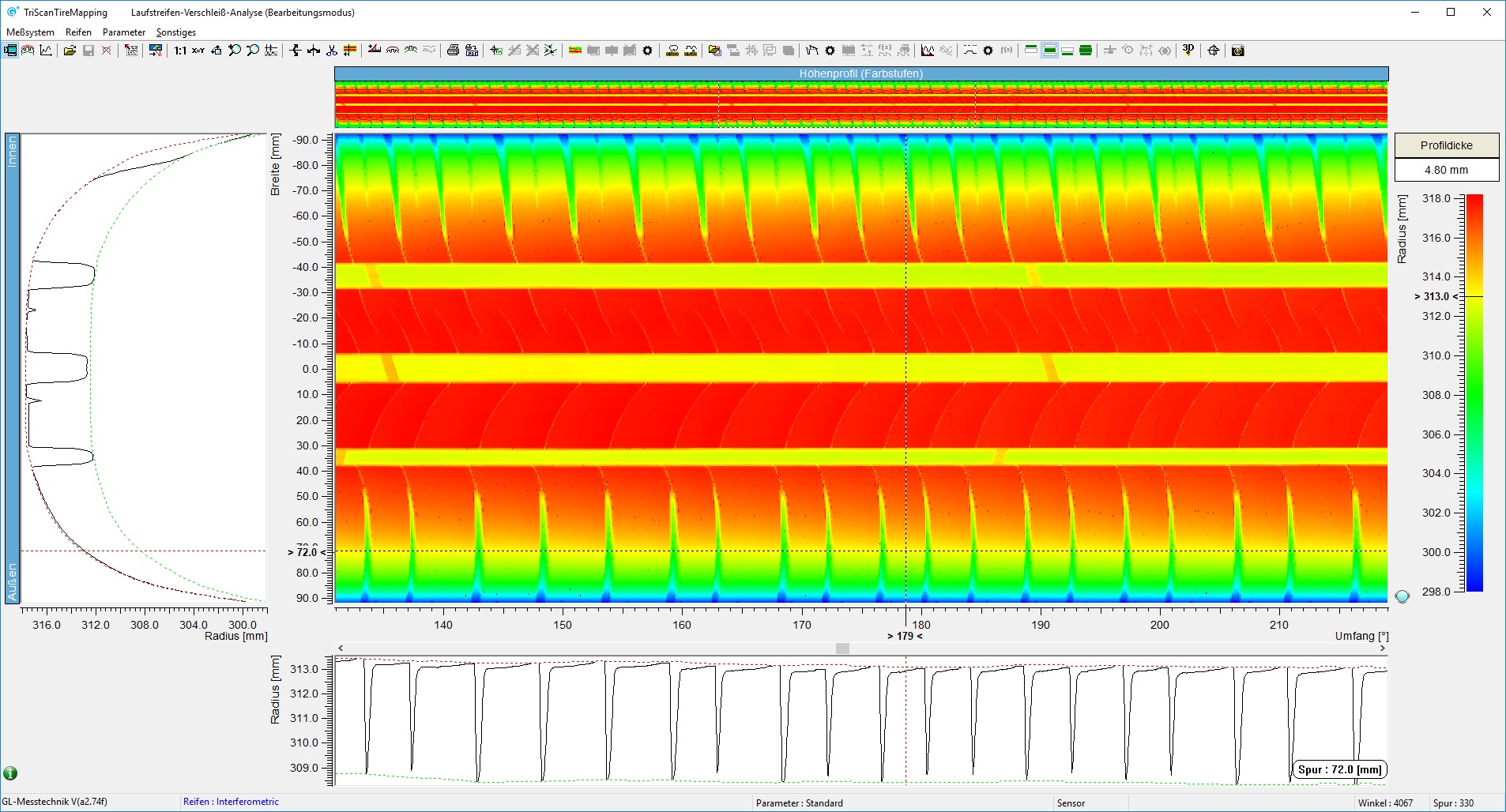

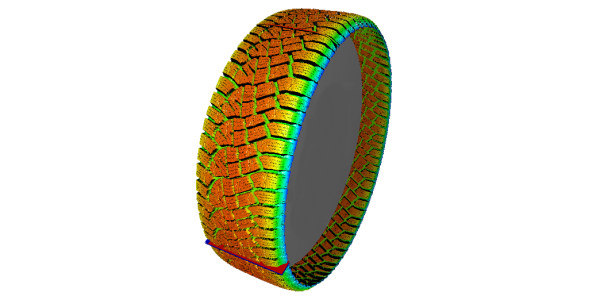

The 3D profile analysis provides relevant information on the tread depth and abrasion. It allows a wear analysis and lifetime estimation of a tire via continuous measuring and comparison of decreasing profile depth. Countless calculation and visualizing functions for the profile evaluation for new and used tires, as well as heel & toe analysis make the system to a multifunctional measurement system.

- Measurement technology: Triangulation line laser sensors

- Laser: Visible/ Red

- Laser class: II / IIM / IIIB

- Data transmission: Digital

- Tire types: PCR / LTR / TBR / OTR

- Tire width: Up to 300 mm

- Measuring time: <10 sec.

- Width resolution: 0.2 mm

- Resolution in circumferential direction: > 8000 scans per rotation

- Non-contact measuring method

- Car-Tire-Scan System