TST - TriScan Tire Fusion

360° measurement system for tires

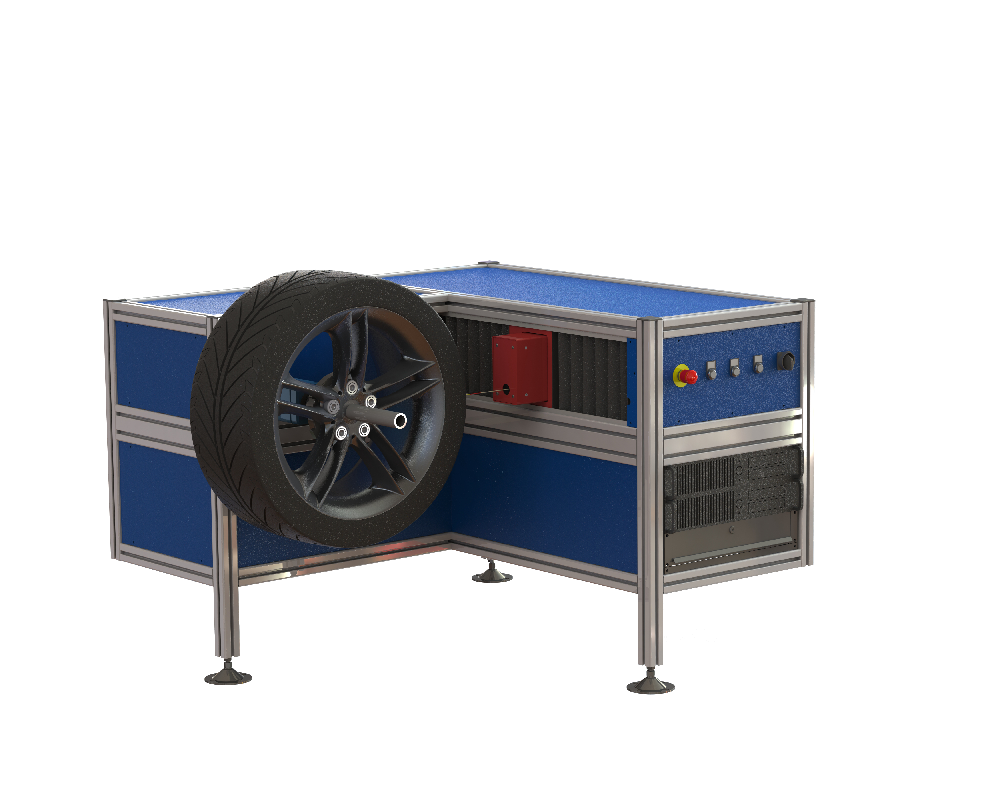

TriScanTire Fusion combines important functions in one compact and easy to relocate device. It is designed for 3D tread analysis, profile measurements and the recording of a 2D cross-sectional profile for car tires.

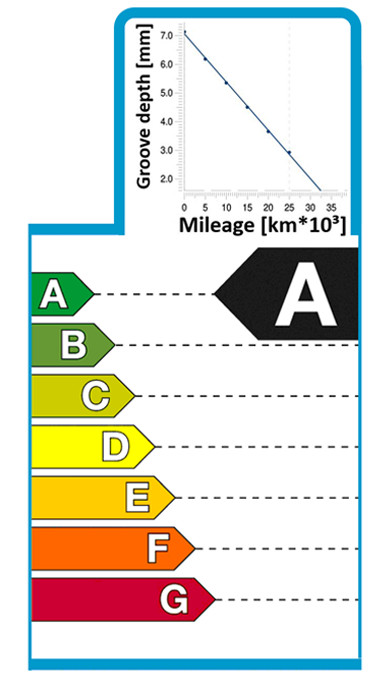

R&D- and Quality departments of tire and automobile manufacturers, as well as independent test institutes use it for tire development, first tire qualification, competitor studies, steady tire quality assurance. Perfect machine to efficiantly produce data for the future tire label.

To achieve the 3D map, the sensor is moved some millimeters (or even less) step by step after each turn and executing the circumference measurement for multiple tracks while the tire/wheel is rotated by the precisely balanced tire driver unit.

The sensor signal is triggered by the encoder pulses 8192 times, resulting in a high resolution scan along one track.

- Measurement technology: Scanning interferometric measurement for shadow reduced results

- Laser class: 2

- Sensor frequency: 8kHz

- Typical measurement time: 360s

- Resolution in circumferential direction: 8192

- Resolution thickness: 0,01mm

- Resolution width: 0,1mm

- Laser spot diameter: 0,085mm

- Tire width: 425mm bei (rim offset=0)

- Tire diameter: 400-900mm

- Wheel weight: ≤ 50kg

- PC: Industrial Desktop PC incl. Windows 10 64bit

- Power supply: 110-230V/ 50-60Hz/ 15A

- Dimensions: 1400mmx1400mm

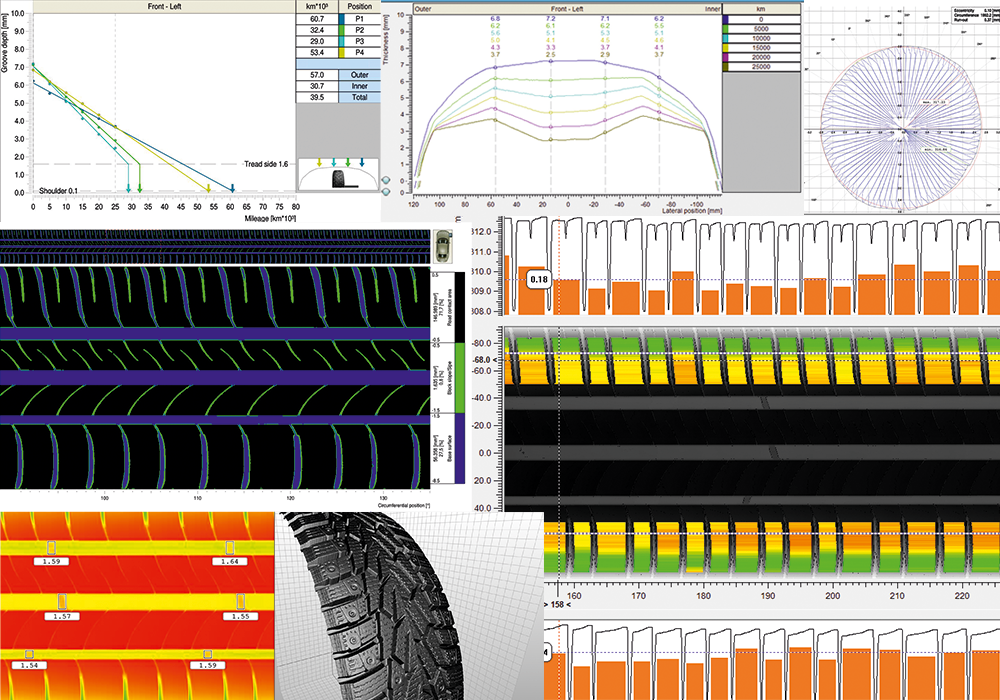

- Wear analysis

- Frequency analysis (tread)

- Heel&Toe analysis (along the track or full profile)

- Milage/ lifetime estimation

- Evaluation of complete sets (for wear analysis of 4 tires)

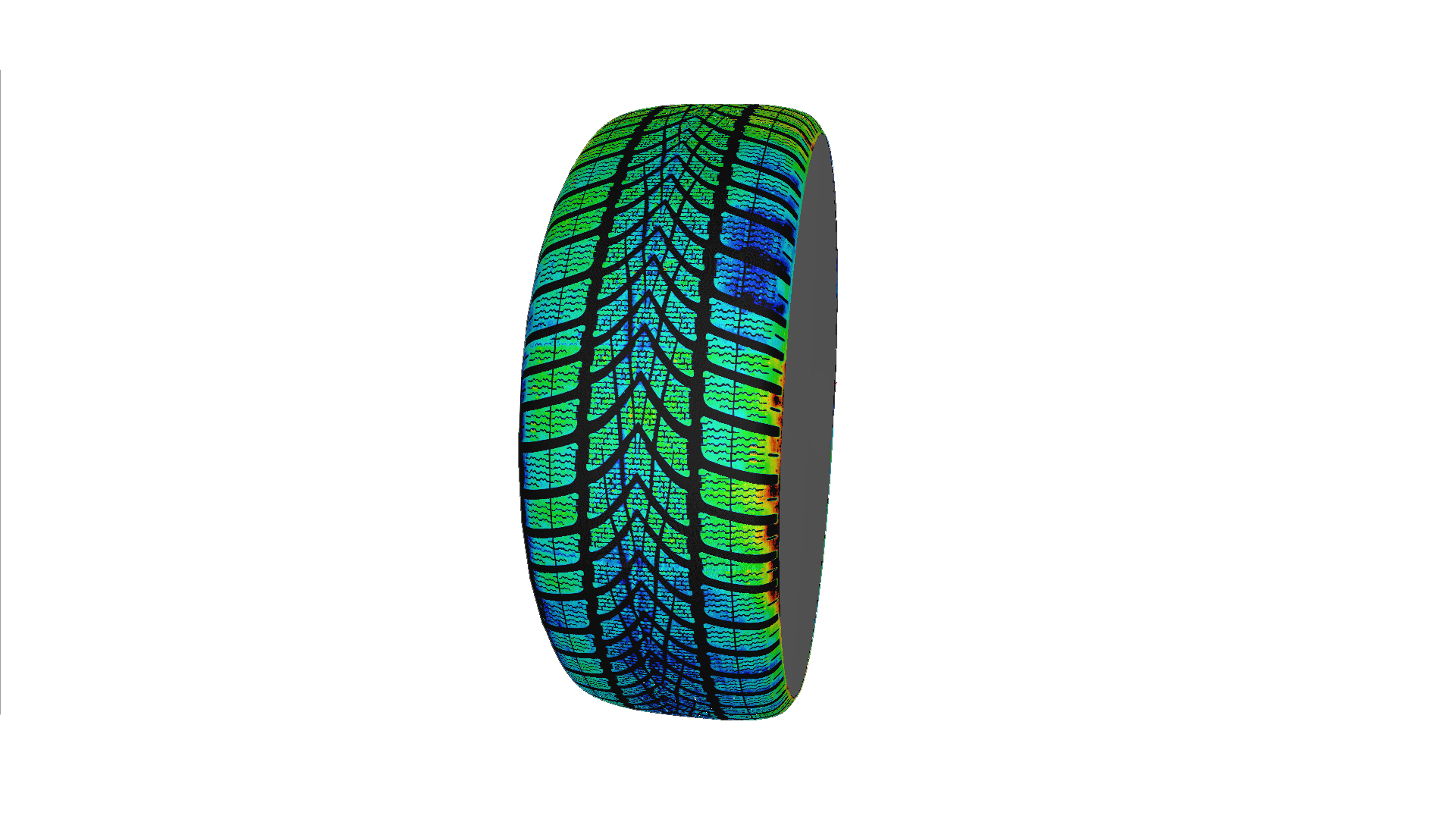

- 3D-mapping of the tire

- Abrasion analysis (cut & chip)

- TWI calculation

- Land to sea ratio

- Envelope calculation

- Surface comparison

- Zoom & dimensioning functions

- Printouts with legends

- Data export functions

- Circumferential measurement

- Run-out measurement (radial)

- Camera interface for adding pictures of tires